| Item |

Specifications |

| Inspection functions |

Applicable tablets |

Uncoated tablets, film-coated tablets, sugar-coated tablet, tablets with printed mark on one or both sides, scored tablets, tablets with engraved marks |

| Tablet size |

Round tablets: 5–12 mm in diameter, 2–8 mm in thickness

Oblong/Oval tablets: 5–12 mm in width, 2–8 mm in thickness, 5–21 mm in length

Contact us for out of range tablets. |

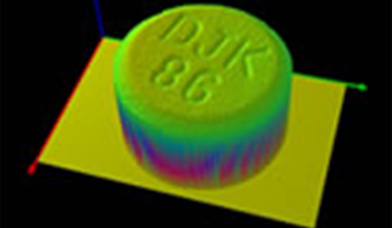

| Inspection items |

Dirt, scratches, foreign particles, cracks, chips, deformation, different color, discoloration, scratched print, blurred print, coating defects and emboss defects |

| Inspection areas |

Cap and body—whole direction and surface, head of capsule |

| Inspection accuracy |

Defects equivalent to a 50μm square or larger black speck |

| Processing capacity |

Actual value: 350,000 tablets/hour (6 mm in diameter)

Will change depending on tablet size and shape. |

| Hardware |

Inspection subsystem |

Optical unit |

6 optical units (4 face, 2 side) lighting source LED |

| Cameras |

3CMOS color line sensor camera x 4, CMOS area sensor camera x 2 |

| Communication |

Touch panel |

| Image processing unit |

Viswill Image Processing Unit |

| Transfer subsystem |

Hopper |

Capacity: 12 L |

| Vibratory feeder |

Processing capacity: Max. 48,000 tablets/min. |

| Flow-control turntable |

Φ596 (diam.) t 0.5, 0–60 rpm |

| Conveyor units |

Suction disc conveyor unit, Suction belt conveyor unit |

| Rejection unit |

Pneumatic system with rejection monitoring function |

| Rejection subsystem |

Defects collection box |

Capacity: 25 L |

| Uninspected collection box |

Capacity: 8 L |

| Pneumatic system |

Suction blower for the bel conveyor (2.2 kW), Suction blower for powder collection (0.75 kW), Suction bolowr blower for the lamp cooling (0.4 kW) |

| Software |

Inspection functions |

Individual and overall judgments; input of sensitivity, inspection condition setting, output of inspection results, simulation function, inspection simulation function |

| Diagnostic functions |

Monitoring of inspection status, monitoring of hardware, self-diagnosis |

| Size and environment |

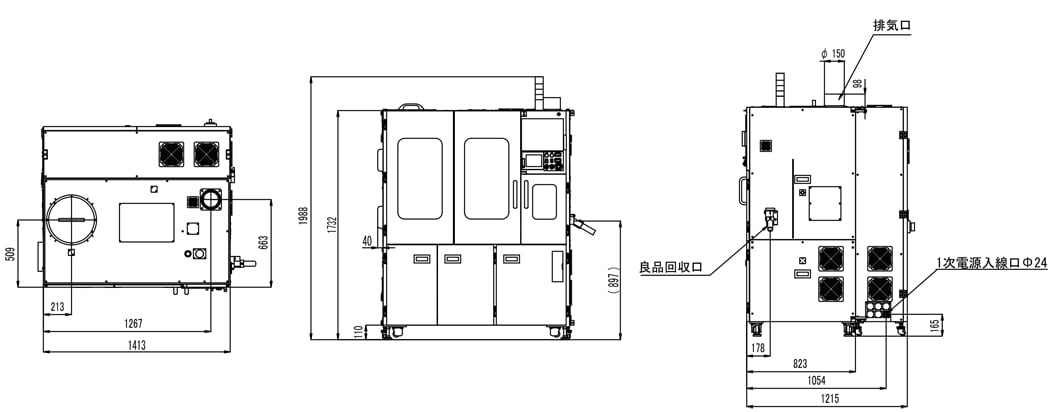

Dimensions |

1,413 (W) x 1,210 (D) x 1,720 (H) |

| Machine weight |

850 kg (inspection unit: 580 kg + control unit: 270 kg) |

| Power supply |

AC 200 VAC (3 phase), 50/60 Hz |

| Power consumption |

5.5kW |

| Pneumatic pressure |

≥ 0.35 MPa |

| Ambient conditions |

Temperature: 10–30 °C

Humidity: 30–70% |

| Exterior |

Stainless steel |

| Exhaust air flow |

Max. 19 m3/min. |