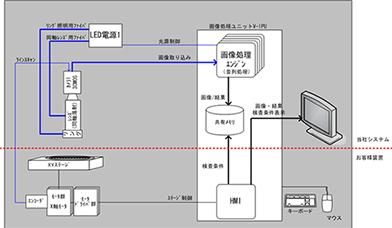

- Outline of the LED Wafer Inspection System

- This case is a custom-made inspection system that Viswill built into the customer's equipment using our image processing and lighting technologies.

Case 1 is an LED wafer inspection system.

The LED wafers to be inspected are automatically supplied to the XY stage for inspection from the loader/unloader.

The supplied LED wafers are set in the inspection stage and transferred by suction conveyor.

The entire LED wafer is inspected using a single color line sensor positioned above.

When inspection (scanning) of the entire LED wafer is completed, the judgment results are displayed on the HMI screen and the operator is notified whether the entire LED chip is conforming or defective.